Piping System Design and Engineering

Develop and design comprehensive plans for the ship’s piping systems, ensuring efficiency, safety, and compliance with regulations.

Isometric and P&ID Development

Create detailed isometric drawings and process and instrumentation diagrams (P&IDs) for accurate representation of piping systems.

Pipe Support Design

Design and implement support structures for pipes, considering the weight, thermal expansion, and vibration to prevent sagging or stress.

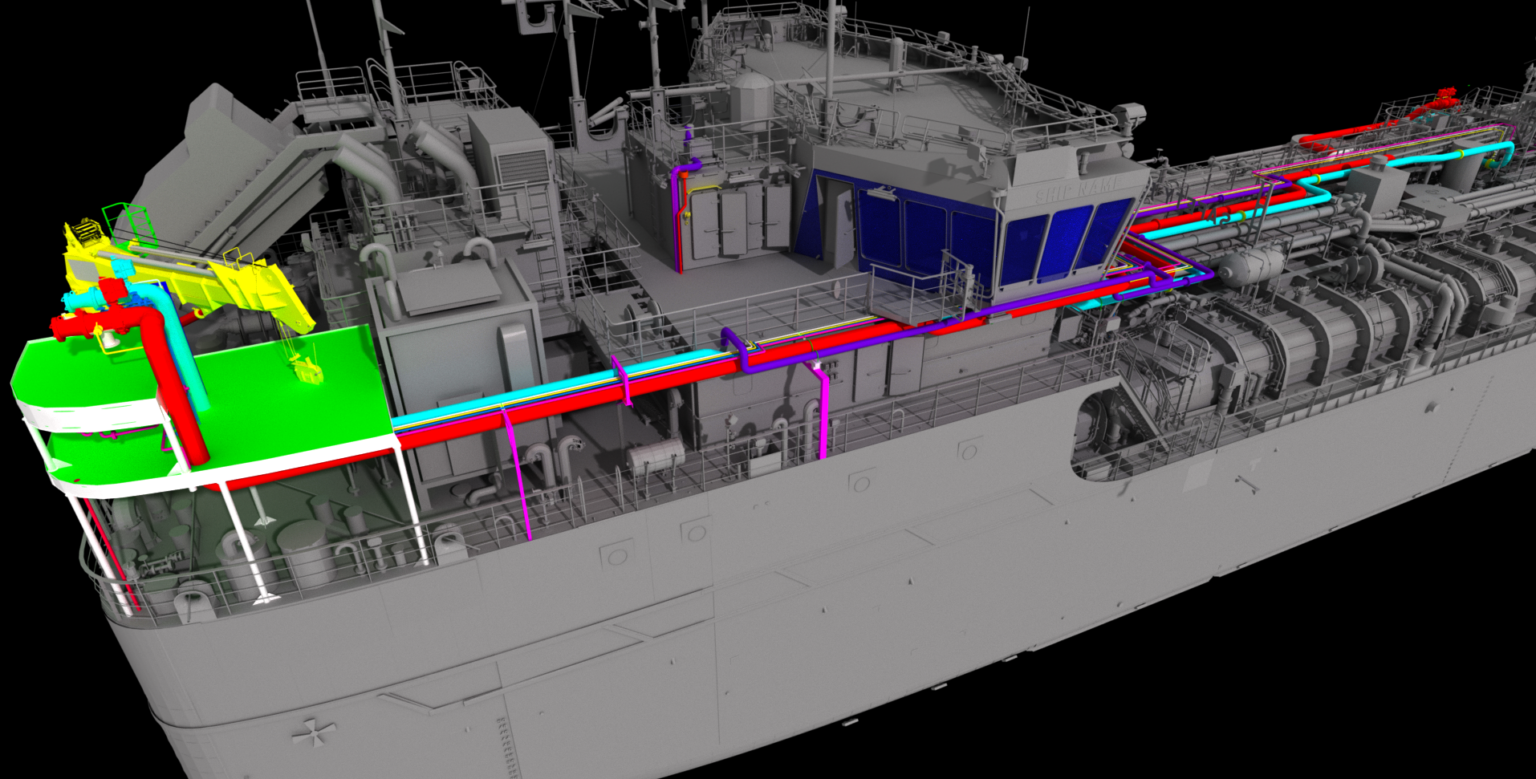

3D Modeling and As-Built Documentation

Create accurate 3D models of piping systems and maintain comprehensive as-built documentation for future reference.

Efficiently orchestrate the blueprint for a vessel’s circulatory lifelines. Our team meticulously engineers the intricate network of pipes, valves, and fittings, ensuring optimal fluid flow, system reliability, and adherence to stringent maritime standards. From conceptualization to detailed design, we navigate the complexities of shipbuilding, integrating innovation and practicality for a seamless and high-performance piping infrastructure that stands up to the rigors of marine environments.

Maintenance & Ship Repair Planning

Develop comprehensive plans for routine maintenance and efficient repair of piping systems to minimize downtime.

Engineering Surveying

Comprehensive analysis and measurement to assess the systems for redesign and maintenance purposes.

Design Optimization

Fine-tuning ship piping layouts for peak efficiency and operational performance.

Material Selection

Rigorously choosing proper materials to ensure the durability and longevity of ship piping systems.

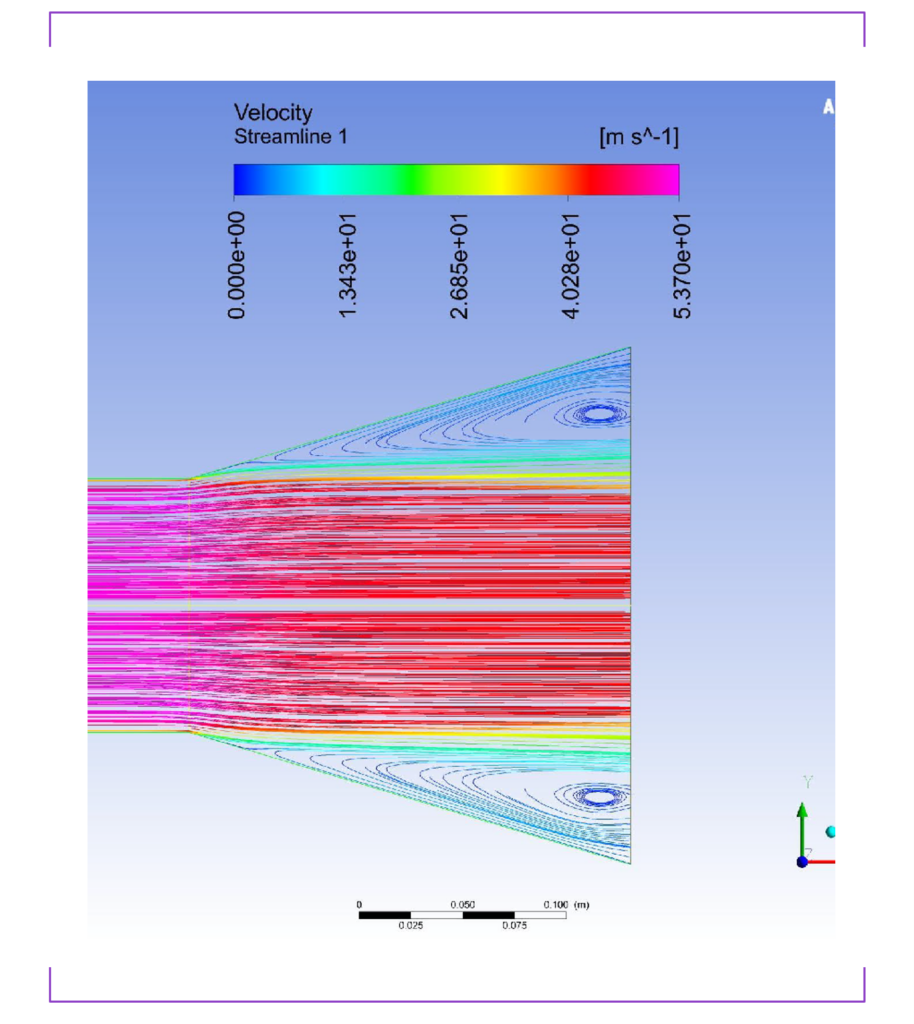

Pipe Stress Analysis

Evaluate the impact of loads and thermal conditions on piping systems to ensure structural integrity and prevent failure.

Utilizes fluid dynamics for pressure loss calculation and flow simulation, ensuring efficient fluid movement. It assesses thermal expansion, vibration, and fatigue, optimizing supports and verifying code compliance for a structurally sound and reliable piping system. This analysis safeguards against issues like excessive stress, deformation, or failure, ensuring long-term performance.